Automatic watches are not created equal; their internal calibers vary significantly in terms of winding efficiency, rotor weight, and directional requirements. Using a single, generic setting for every timepiece can lead to incomplete winding or unnecessary mechanical stress. WatchMatic solves this by offering precision adjustments, ensuring that a high-torque Audemars Piguet receives a different rotation profile than a standard TAG Heuer.

The Mechanical Variance of Calibers

The reason a "one-size-fits-all" approach fails in watch winding is rooted in the architecture of the movement. The rotor - the oscillating weight that winds the mainspring - is engineered to respond to specific kinetic thresholds.

1. Variations in Turns Per Day (TPD)

TPD is the number of full rotations a winder performs in 24 hours.

- Under-winding: If the TPD is too low, the watch will eventually lose its power reserve and stop, even while on the winder.

- Optimal Winding: Most modern timepieces, such as those from Rolex, require winder settings 650 TPD to stay at peak performance. However, some complex heavy-duty calibers may require 800 or even 1,000 TPD to maintain a full charge.

2. The Weight of the Rotor

Different brands use different materials for their rotors. High-end horology often utilizes 22k gold or tungsten for the oscillating weight to increase winding efficiency. Because a gold rotor is heavier and has more inertia, the winder must be able to handle that weight with a consistent, smooth motor speed. WatchMatic winders use high-torque Japanese motors specifically designed to maintain constant velocity regardless of the watch's weight.

3. Directional Sensitivity

As previously explored, many movements are unidirectional. For example, some chronograph movements only wind when the rotor spins clockwise. If your winder doesn't allow you to isolate that direction, the watch will receive zero energy during the counter-clockwise cycles. This is why independent control is a non-negotiable feature for serious collectors.

4. Protecting the Slipping Spring

While modern watches have a "slipping spring" to prevent overwinding, you shouldn't rely on it constantly. By matching the exact winder settings TPD recommended by the manufacturer, you ensure the mainspring stays wound without frequently triggering the slipping mechanism, which reduces internal friction and extends the time between services.

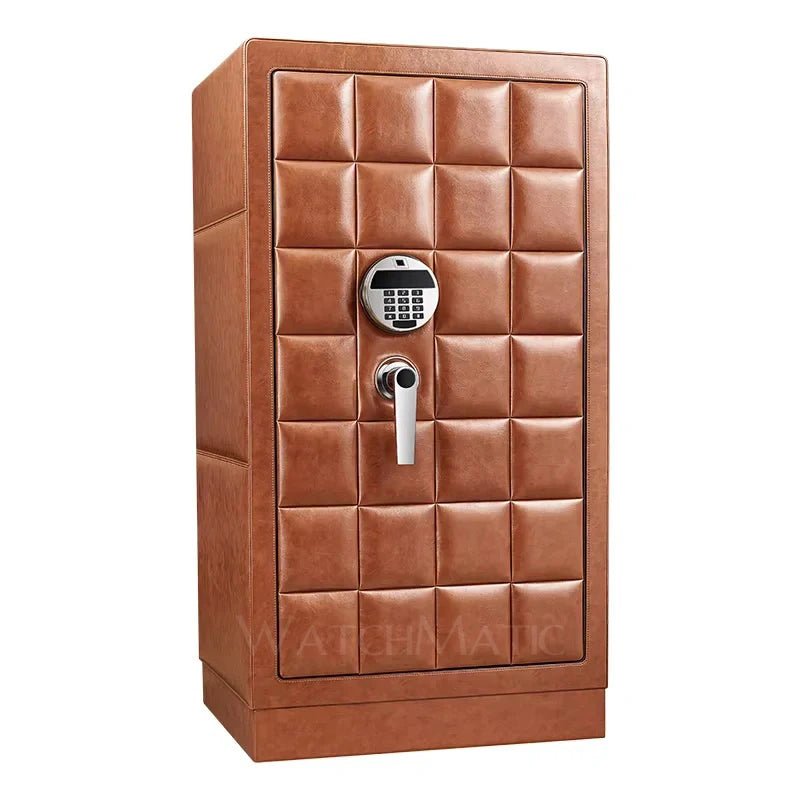

The Solution for Diverse Collections

If you manage a mixed collection, the best way to handle these varying requirements is through a centralized watch winder safe box. This allows you to set the perfect "prescription" for each individual watch in one secure, organized location. At WatchMatic, we provide the technology to ensure your watches are treated according to their unique mechanical DNA.